-

Casa

-

Prodotti

-

Frantoio a cono

-

Frantoio a cono Symons

-

Frantoio a cono idraulico monocilindrico

-

Frantoio a cono GP

-

Frantoio a cono idraulico multicilindrico

-

Frantoio a cono HP

-

Frantoio a cono primaverile

-

Frantoio a cono composto

- Frantoio a mascelle

-

PE Mascella Crusehr

-

Frantoio a mascelle serie C

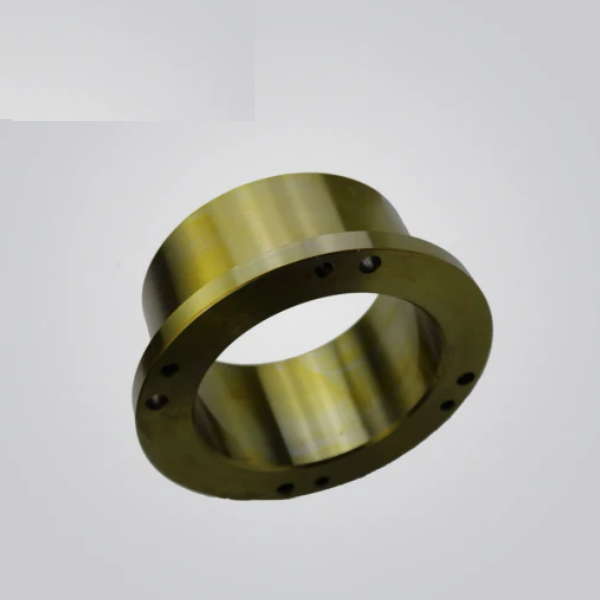

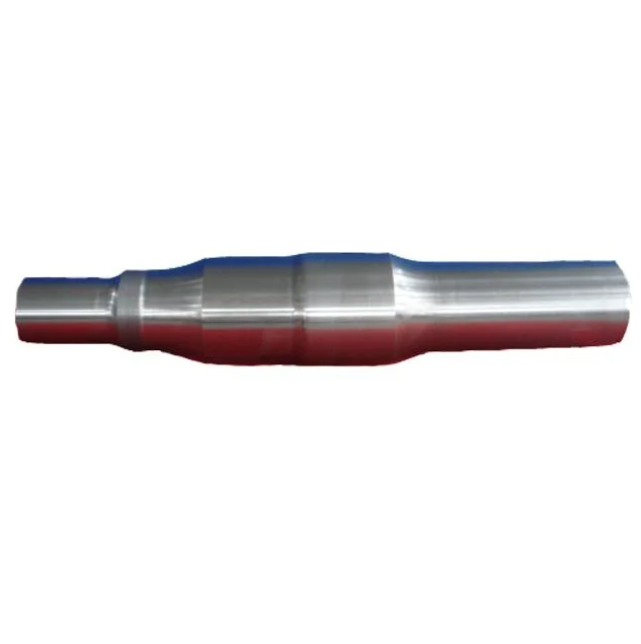

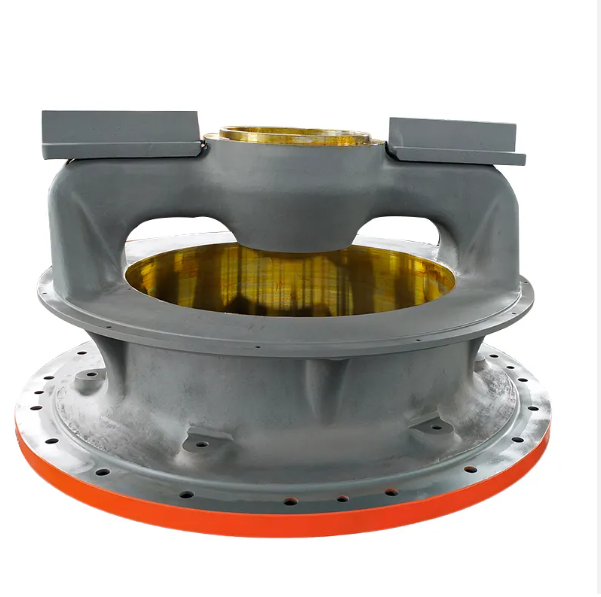

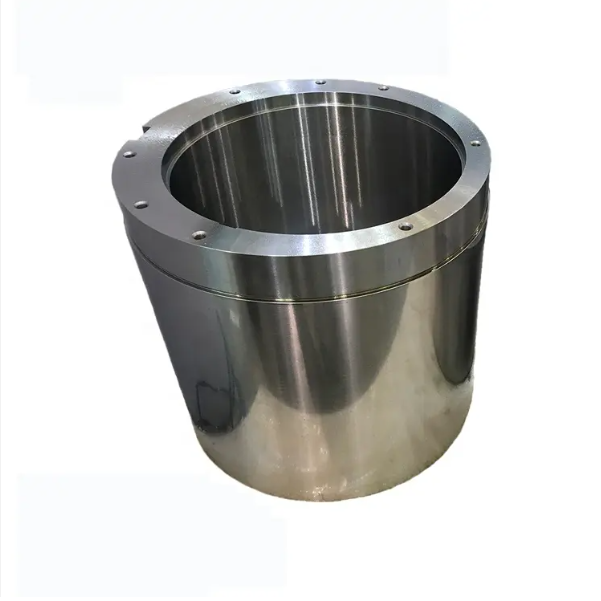

- Parti del frantoio a cono

-

Parti del frantoio a mascelle

- Rulli di macinazione ad alta pressione

-

Vaglio vibrante

-

Mulino a palle

-

Parti del mulino a palle

-

Frantoio a cono

- Notizia

-

Caso

-

Mostra di fabbrica

-

Officina di lavorazione ShiLong

-

Spettacolo di attrezzature minerarie ShiLong

-

Spettacolo di pezzi di ricambio per l'estrazione mineraria di ShiLong

-

Ispezione ShiLong

-

Magazzino pezzi di ricambio ShiLong

-

Laboratorio di test ShiLong

-

Laboratorio di fusione di ShiLong

-

Lavorazione di pezzi di ricambio ShiLong

-

Officina di lavorazione ShiLong

-

Contattaci

-

Chi siamo